In a world where machines do the heavy lifting, industrial automation systems are the unsung heroes of efficiency. They’re like the over-caffeinated workers of the manufacturing realm—never tired, always precise, and ready to tackle the most tedious tasks with a smile. Imagine a factory where robots dance through assembly lines, making mistakes as rare as a unicorn sighting. That’s the magic of automation!

Table of Contents

ToggleOverview of Industrial Automation Systems

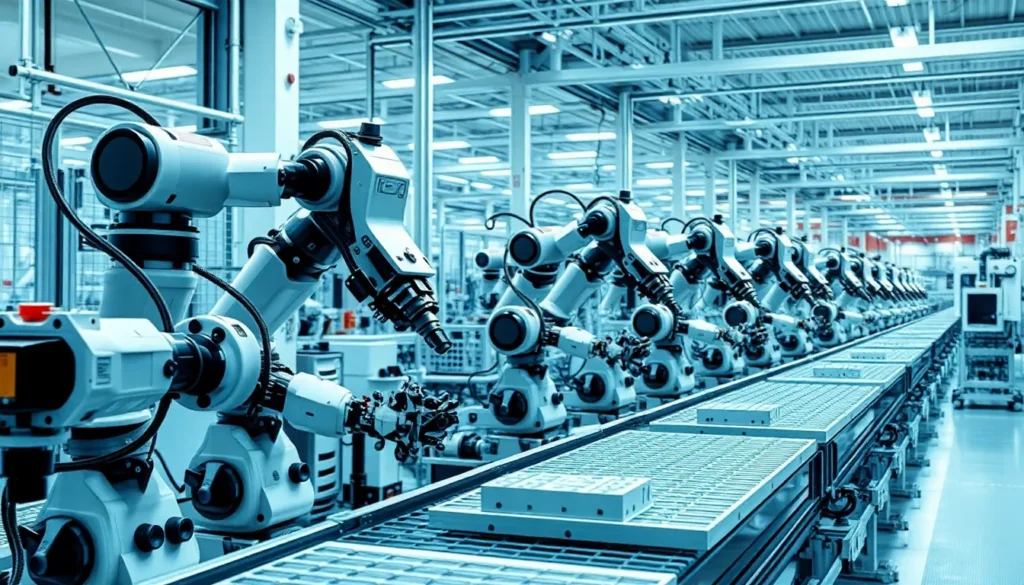

Industrial automation systems integrate technology and processes to streamline operations in manufacturing environments. These systems enhance production efficiency and minimize human intervention. They control machinery, processes, and various equipment, maximizing output while ensuring consistency.

Key components of industrial automation systems include sensors, actuators, controllers, and software. Sensors collect data from the environment, enabling real-time feedback. Actuators respond to controller signals, executing precise movements in machinery. Controllers process incoming data and send commands, ensuring all elements function harmoniously. Software oversees these processes, providing user interfaces for monitoring and control.

Manufacturers recognize the value of automation. It reduces operational costs by minimizing labor needs and decreasing errors. Furthermore, automation enhances safety by taking over dangerous tasks, thereby protecting workers. Efficiency achieves higher throughput levels, enabling companies to meet customer demands effectively.

In addition to traditional automation, industry 4.0 introduces smart manufacturing concepts. This approach utilizes the Internet of Things and advanced analytics to foster interconnected systems. Data-driven insights allow manufacturers to make informed decisions, ensuring adaptability in a rapidly evolving market.

Automation is not limited to large-scale operations. Small and medium enterprises embrace these systems to stay competitive. Solutions are available for various applications, from simple machinery controls to complex production lines. Customizable options cater to specific needs, making automation accessible for diverse industries.

The standardization of automation technologies encourages seamless integration across platforms. PLCs, SCADA systems, and HMIs work together to build cohesive operations. Collaborative robots, or cobots, assist human workers in various tasks, further enhancing productivity without sacrificing jobs.

Overall, industrial automation systems represent a transformative shift in how manufacturing operates, driving innovation while fostering growth.

Key Components of Industrial Automation Systems

Industrial automation systems consist of several critical components that work in unison to enhance production efficiency. These include sensors, actuators, control systems, and human-machine interfaces, each contributing to seamless operations in manufacturing environments.

Sensors and Actuators

Sensors detect physical conditions like temperature and pressure, providing essential data for operation. By converting these readings into signals, sensors enable systems to respond to changes dynamically. Actuators follow suit, translating control signals into physical movements. They drive mechanical systems, moving components on assembly lines with precision. Together, sensors and actuators create a responsive environment where processes adjust in real-time.

Control Systems

Control systems manage interactions between various elements in industrial automation. Programmable logic controllers (PLCs) form the backbone, executing programmed instructions to maintain consistency in operations. These systems analyze data from sensors, allowing them to make decisions that enhance performance. Additionally, distributed control systems (DCS) provide a higher level of supervision, coordinating multiple processes across facilities. Effective control systems optimize productivity while ensuring safety.

Human-Machine Interfaces

Human-machine interfaces (HMIs) bridge the gap between operators and machinery. They present data in a user-friendly manner, allowing operators to monitor systems easily. Clear visualizations and alerts facilitate quick decision-making and troubleshooting. Furthermore, advances in HMI technologies enhance user engagement, providing interactive controls that improve operational effectiveness. HMIs ensure that automation complements human oversight, fostering collaboration on the factory floor.

Benefits of Implementing Industrial Automation Systems

Industrial automation systems significantly enhance operational capabilities, leading to numerous advantages in manufacturing environments.

Increased Efficiency and Productivity

Automatic processes streamline production cycles, enabling faster turnaround times. Robots and machines complete repetitive tasks without fatigue, ensuring constant output. Consequently, manufacturers witness a notable uptick in productivity levels. Flexibility in automation allows for quick adjustments, accommodating varying production demands with minimal downtime. Data integration provides real-time insights, allowing for informed decision-making that directly influences efficiency. Overall, these systems facilitate the production of higher quality goods, meeting market needs more effectively.

Improved Safety and Reduced Errors

Automation minimizes human exposure to hazardous tasks, creating a safer work environment. By undertaking dangerous operations, machines significantly reduce injury risks associated with manual work. Additionally, consistency in processes leads to a marked decrease in errors and defects. Automated systems utilize precise algorithms, ensuring repeatability and accuracy. This precision fosters adherence to quality standards, which is crucial for maintaining customer satisfaction. Enhanced safety measures also promote employee well-being, contributing to a more productive workforce.

Challenges in Industrial Automation Systems

Industrial automation systems face several obstacles that impact their implementation and effectiveness.

High Initial Investment

High setup costs present a significant challenge for many businesses considering automation. Expenses associated with purchasing equipment such as robots, sensors, and control systems can accumulate quickly. Additionally, organizations must invest in software and training for personnel, further increasing the total expenditure. Without a clear return on investment strategy, some companies hesitate to make the necessary financial commitment. Over time, however, many organizations realize the potential for long-term savings and efficiency gains that justify initial spending.

Integration with Existing Systems

Integrating new automation systems with current infrastructure often proves complicated. Legacy systems may not support the latest technologies, leading to compatibility issues. Businesses also face the challenge of data synchronization between new automation tools and older systems, which can disrupt operations. System integration requires careful planning and sometimes significant redesign of existing processes. Working closely with automation experts can ease the transition and foster a smoother integration experience, allowing organizations to maximize the benefits of their new systems.

Future Trends in Industrial Automation Systems

Industrial automation is evolving rapidly, reflecting advancements in technology and industry demands. Key trends shaping this future include artificial intelligence and enhanced connectivity through the Internet of Things.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) improves decision-making in industrial automation systems. AI algorithms analyze large data sets, enabling predictive maintenance and optimizing production schedules. Machine learning enhances system adaptability by tailoring operations based on performance metrics, promoting continuous improvement. Additionally, AI-powered robots can learn tasks through experience, further increasing efficiency while reducing dependency on human intervention.

IoT and Connectivity Advancements

The Internet of Things (IoT) revolutionizes how industrial automation systems operate. Smart devices connected to the IoT provide real-time data, enhancing visibility across production processes. Improved connectivity facilitates the collection and analysis of operating data, leading to timely adjustments based on market demands. Manufacturers leverage these advancements to create more responsive and resilient supply chains, ensuring seamless integration with existing infrastructure. More importantly, enhanced connectivity supports collaboration between machines and operators, fostering a dynamic production environment.

Industrial automation systems are reshaping the manufacturing landscape by driving efficiency and productivity. As businesses embrace these technologies, they unlock the potential for streamlined operations and enhanced safety. The integration of advanced components like sensors and AI ensures that manufacturers can adapt to changing market demands while maintaining quality standards.

Despite challenges such as initial costs and integration complexities, the long-term benefits far outweigh the hurdles. Future trends promise even greater advancements, paving the way for smarter and more interconnected production environments. As the industry evolves, embracing automation will be essential for companies aiming to remain competitive and innovative in a rapidly changing market.